Ease of operation

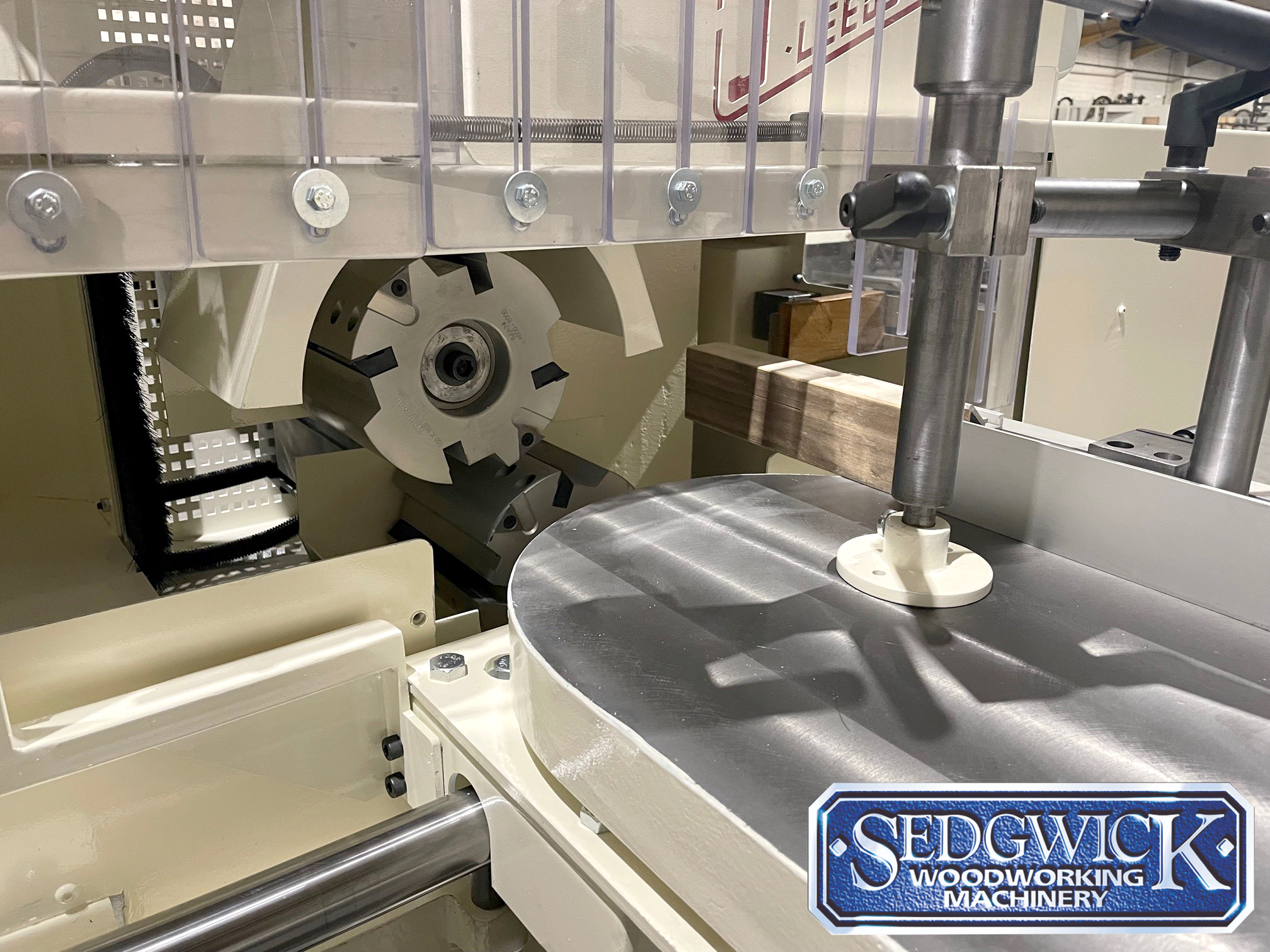

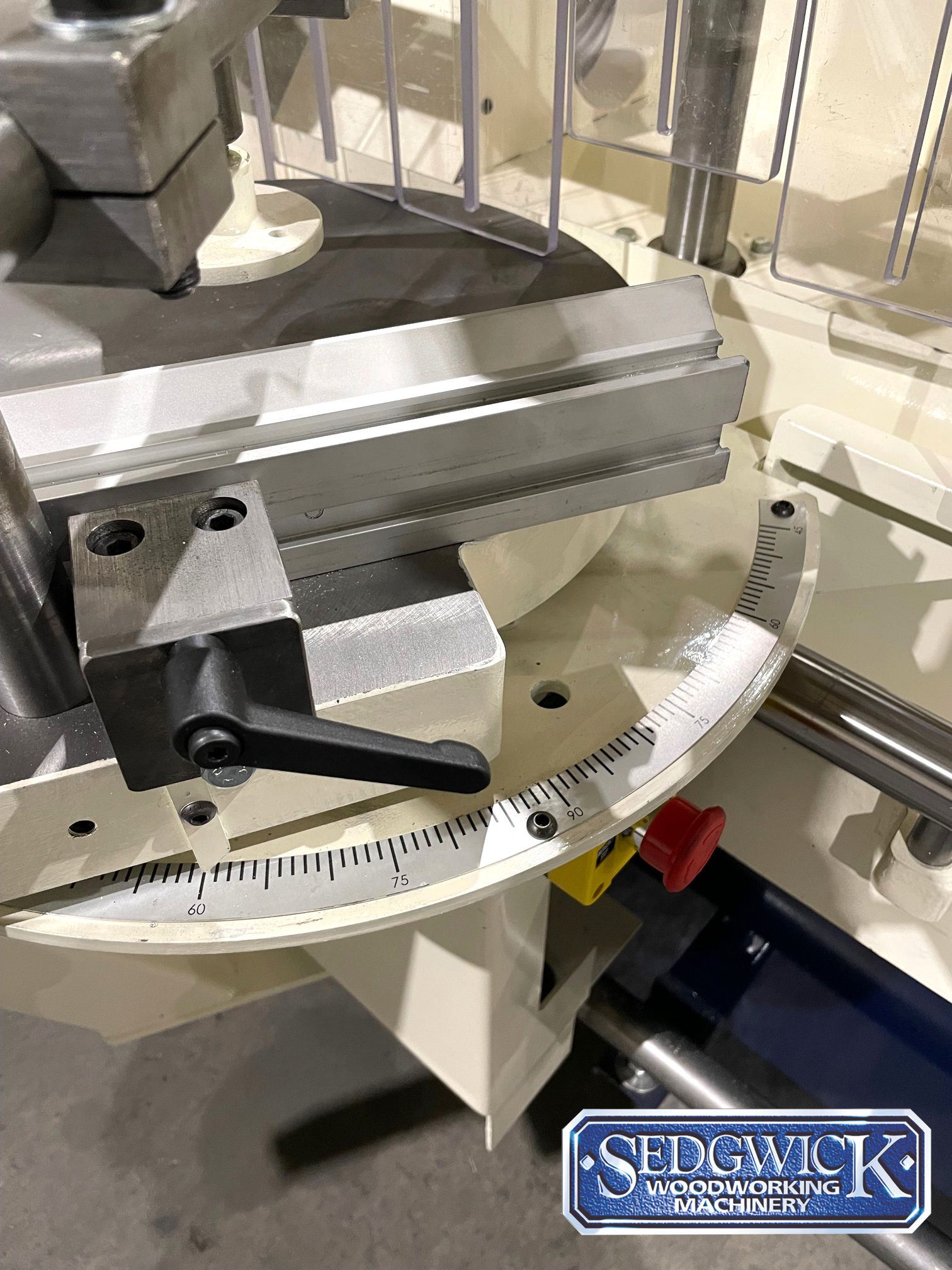

Taking only minutes to set up, the Sedgwick TESH is easy to use and accurate in operation. Work is positioned on the rolling table against a depth stop and a fence, and is secured by a cam action clamp. Its end is then passed between two horizontally mounted cutterheads which machine the top and bottom cheeks of the tenon. The tenon width is set by raising or lowering the top motor, and its position on the timber by raising/lowering the two motors in tandem. Variations in shoulder length are set using a multi-position depth stop, and staggered tenons are achieved by simple handwheel adjustment of the top motor.

Versatility

Stepped tenons, splayed tenons, scribed tenons, double tenons, and multiple bridles are all possible on this versatile machine. Combinations of 90 degree and bevelled cutting discs with appropriate spacers can also be fitted to produce interleaved joints as used in sash window construction.

Construction

The Sedgwick TE/TESH is designed and built to withstand continuous production use. Its cast iron base, column and slideways provide a rigid and durable mainframe assembly, and the 2.2Kw motors supply ample power. The generously proportioned cast iron sliding table is mounted on bearing equipped hardened steel rollers for minimum wear, and cutterhead slide movements are easily adjusted on dovetail slides for ease of maintenance.

Safety Features

The TE/TESH offers all of these safety features as standard:

- Automatic braking

- Starters with thermal overload, no volt release protection and lock off emergency stop switch.

- High performance lightweight cutter blocks with chip limiting devices

- Large diameter dust extraction outlets

- One piece front cutter guard

- Front & rear table guards

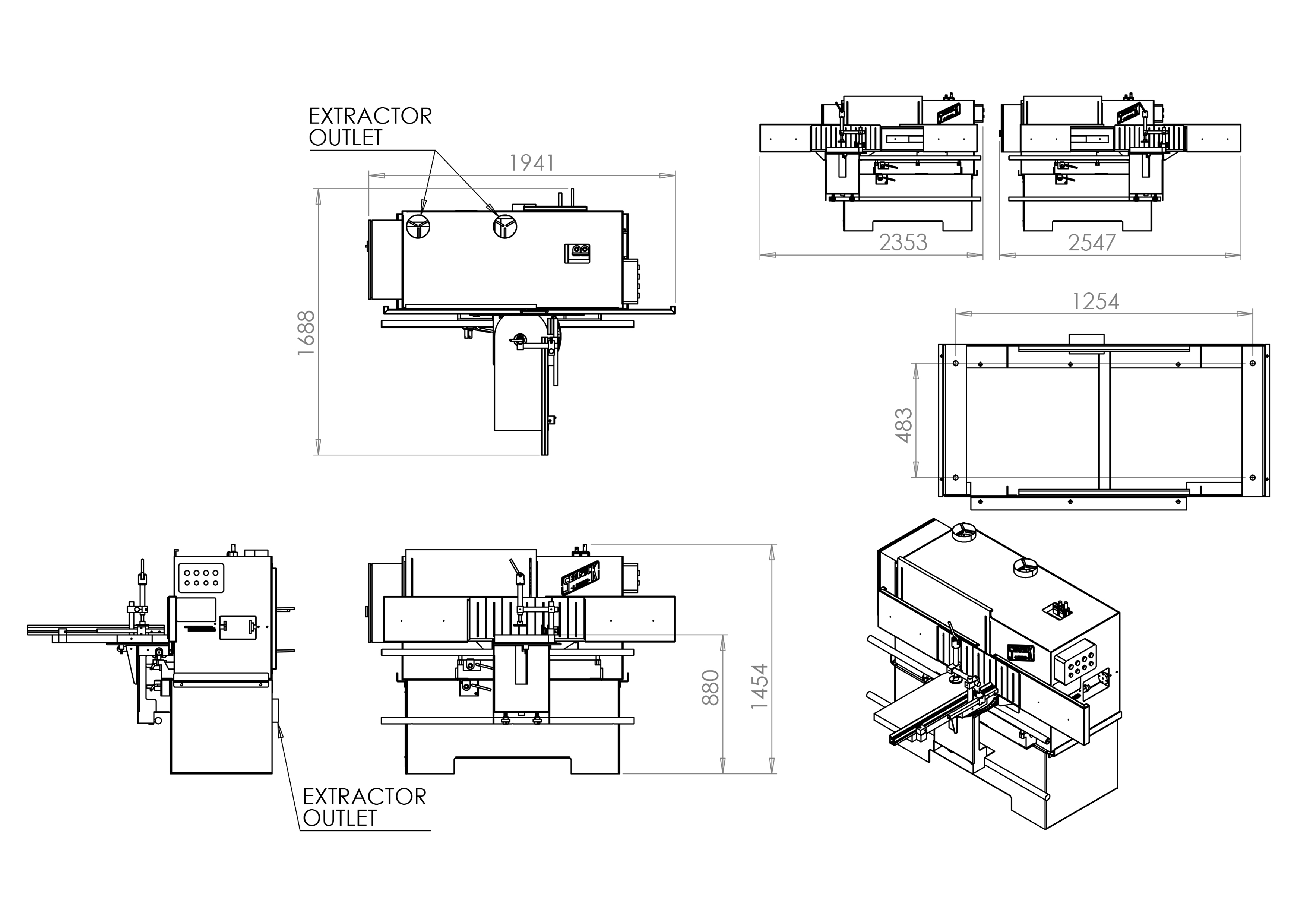

Machine Specification

Machine Specification

| TIMBER CAPACITY | 150 x 300mm |

| MAXIMUM TENON LENGTH | 150mm |

| TABLE SIZE mm | 765 x 340 (765×300 useful) |

| TABLE WORKING HEIGHT | 890mm |

| TABLE QUADRANT ADJUSTMENT | +/- 0-60 degrees |

HORIZONTAL TENONING HEADS

| CUTTERBLOCKS | 150 x 150 x 30mm |

| MAX TOOLING DIAMETER | 155mm (BOTTOM) 200mm (TOP) |

| VERTICAL ADJUSTMENT OF BOTTOM CUTTERBLOCK | -2mm / + 77mm |

| VERTICAL ADJUSTMENT OF TOP CUTTERBLOCK | +4mm / + 150mm |

| HORIZONTAL ADJUSTMENT OF TOP CUTTERBLOCK | -50mm /+ 20mm |

| DUST EXTRACTION OUTLETS | 2 x 150mm |

| MOTOR RATING | 2 x 2.2 Kw (S6 40%) |

| FULL LOAD CURRENT | 4.75 AMPS |

| STARTING CURRENT | 35 AMPS |

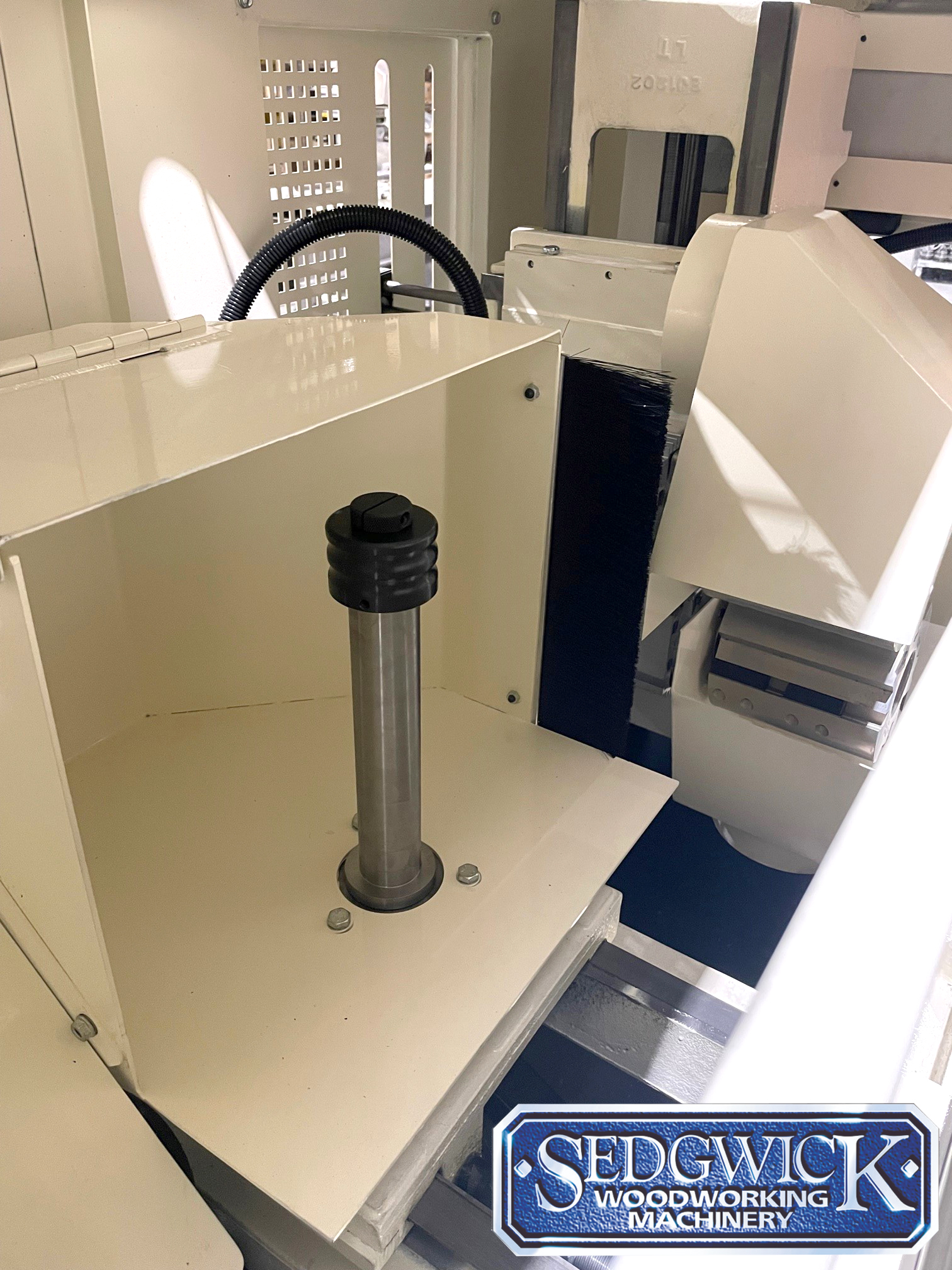

VERTICAL SPINDLE

| SHAFT DIAMETER | 40mm |

| EFFECTIVE LENGTH OF SHAFT | 205mm |

| VERTICAL MOVEMENT | 112mm |

| HORIZONTAL MOVEMENT | 150mm |

| MAXIMUM TOOLING DIAMETER | 350mm |

| SPINDLE SPEED | 4000 RPM |

| MOTOR RATING | 5.5Kw (S1) |

| FULL LOAD CURRENT | 11.5 AMPS |

| STARTING CURRENT | 69 AMPS |

ELECTRICAL

| VOLTAGE / FREQUENCY | 3 PHASE + EARTH; 400/230 V – 50/60 Hz |

| REQUIRED FUSE SIZE | 25A/ph |

| REQUIRED CABLE SIZE | 4mm2 |

Pricing

| Product Code | Description |

Price ex VAT |

| TE350-3 | Single End Tenoner 380-420 volts 3 phase 50 hz 2 x 2.2 kW c/w 5.5kW Scribing Hd |

£14600.00 |