Construction

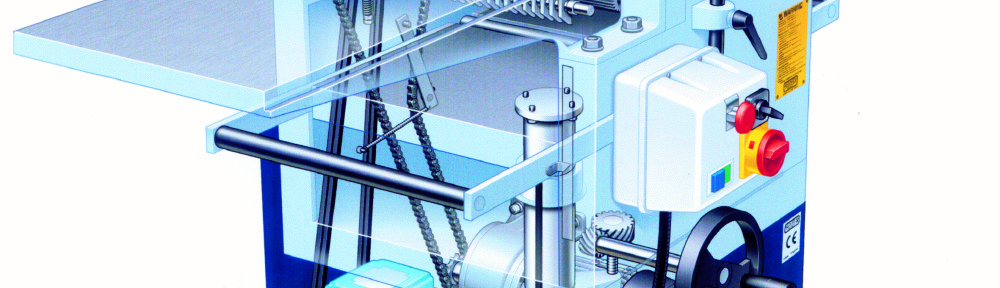

The Sedgwick MB308 planer thicknesser is designed and built for precision, long life and minimum maintenance. Its rigid mainframe assembly gives exceptional stability, and accurately houses the feed and cutterblock bearings, and the infeed and thicknessing tables.

The Cutterblock

A large diameter four knife TERSA cutterblock provides improved finish, and runs in ‘sealed for life’ bearings for minimum maintenance.

Driving the cutterblock is an industrial motor via two heavy section vee belts which, combined with the centrifugal force of the large diameter block, provides ample power.

Surface Planing

The cast infeed table (which on the MB/CP planer has increased length for accurate surfacing) rises and falls in square gibs for long term accuracy, and is fitted with a rule showing depth of cut. A generously proportioned cast iron fence is then mounted off the table on a cast iron bracket. The fence can be tilted between 90º – 45º making it suitable for bevel work and chamfering, and is easily returned to 90º via a positive stop. Adjustable shaw guards are also supplied.

Thicknessing

For long term accuracy, and to avoid time consuming mode changes, the surfacing tables remain in place when thicknessing, utilising instead a dual function chip collection hood.

The thicknessing table is again cast iron and is mounted on a large diameter precision ground pillar to ensure precise and parallel positioning, with an off-centre lock for added rigidity. The MB/CPs thicknessing table is fitted with extension rollers, which run in self-lubricating bushes. Large diameter steel feed rollers (one spiral-fluted the other rubber coated) are driven by an industrial geared unit, which on three phase machines has two speeds. The feed rollers run in self-lubricating bushes and are driven from the geared unit by a heavy duty chain for efficient and constant feeding of demanding production work and difficult stock.

Safety Features

The drive assembly is totally enclosed by the rear machine guard, removal of which provides easy access to the motor drive assembly for any necessary maintenance. The cutterblock is guarded at the rear by a fixed guard attached to the fence, and at the front by a bridge type guard.

Specification

|

MB |

|

| SURFACE CAPACITY |

308 mm |

| THICKNESSING WIDTH |

308 mm |

| THICKNESSING DEPTH |

230 mm |

| SURFACE TABLE LENGTH |

1500 mm |

| INFEED TABLE LENGTH |

850 mm |

| SURFACE TABLE HEIGHT |

900 mm |

| THICKNESSING TABLE LENGTH |

600 mm |

| TABLE LENGTH OVER EXTN ROLLERS |

1000 mm |

| CUTTERBLOCK DIAMETER |

102 mm |

| CUTTERBLOCK KNIVES |

4 TERSA |

| CUTTERBLOCK SPEED |

4000rpm |

| FEED ROLLER DIAMETER |

51 mm |

| FEED SPEEDS |

3 PHASE 4.5 & 7 m/min 1 PHASE 6 m/min |

| FENCE SIZE |

750 x 120 mm |

| TILTING ANGLE OF FENCE |

0O – 45O |

| CHIP EXTRACTION OUTLET DIA. |

125mm |

| VOLTAGE / FREQUENCY |

3 PHASE + EARTH ; 400/230 V – 50/60 Hz 1 PHASE + N + EARTH ; 230V / 50/60 Hz |

| CUTTERBLOCK MOTOR RATING |

3 PHASE 3.0 Kw 1 PHASE 3.0 Kw |

| FEED MOTOR RATING |

0.375 Kw |

| MOTOR FULL LOAD CURRENT IN AMPS |

3 PH C’BLOCK 6.5A 1 PH C’BLOCK 14.6A 3 PH FEED 1.5/1.3 1 PH FEED 2.8A

|

| STARTING CURRENT IN AMPS |

3 PHASE 39A 1 PHASE 87.6A |

| REQUIRED FUSE SIZE IN AMPS |

3 PHASE 20A/ph 1 PHASE 40A |

| REQUIRED CABLE SIZE |

3 PHASE 2.5mm2 1 PHASE 40A |

Pricing

| Product Code | Description |

Price ex VAT |

| MB-3/TERSA | 308×230 Planer Thicknesser 380-420 volts 3 phase 50 hz 3.0 kW * |

£6100.00 |

| MB-1/TERSA | 308×230 Planer Thicknesser 220-240 volts 1 phase 50 hz 3.0 kW * |

£6200.00 |

| 310mm Reversible HSS Tersa Knife Set (4) |

£57.00 |

|

| * Extra for Spiral Cutterblock |

£450.00 |

|

|

|